Research and development of manufacturing technology contributing to improvement in the manufacturer’s management.

The “Lever mechanism” is MANYO’s unique core technology.

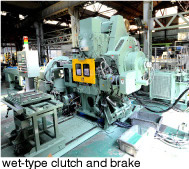

Billet shears utilizing this technology enjoy an appreciation of the top share in Japan. MANYO uses the development of further advanced technology to produce continuous improvement in the lever mechanism, noise reduction, and yield as a foundation of technology and service.

By doing this, MANYO quickly satisfies needs generated at customers’ worksites, in order to keep contributing to solving problems at production sites.

Patented unique “Lever mechanism”

The cutting machine works satisfactorily only when these three factors are in place and interlocked organically.

We believe that these three factors are major principles in design and manufacturing,

and we pursue the development of superior cutting machines by utilizing our expertise and experience.

Environmental consciousness

We have acquired “ISO14001”, since we recognize the environment around our factory as being of vital importance. We also recommend our business partners and employees to promote environmental management.

Improvement in production efficiency

We cope with the need to reduce labor costs by full automation, using fully automatic beam-type transfer devices and fully automatic manipulators. We have been developing our original automation technology to achieve both lower costs and higher productivity.

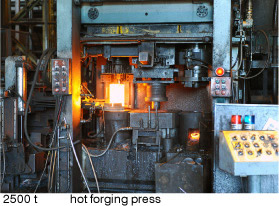

Increase in yield

We are pursuing improvements in yield for production processes up to the final products, and are also pursuing cost reduction in each process (near-net shape forming). We will continue to contribute to the forming of high precision forging products with developments in the hot, warm, and cold forging press and hot forging roll machine.