FR

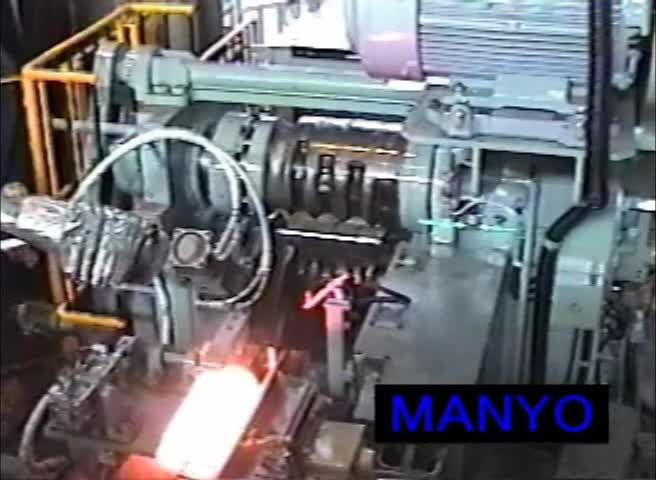

Innovative design of forging roll enables small lot production of many products.

Features(Forging roll main unit)

- Unique gear transmission mechanism is intended for compactification of the main unit.

- Oil bath in the main unit secures complete lubrication of the drive system.

- Full automatic centralized circulating lubrication system provided for metal components eliminates unnecessary concern about maintenance.

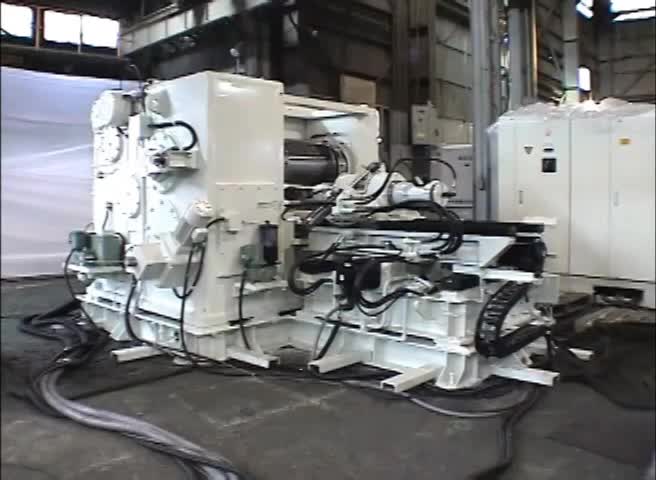

Features(Auto manipulator)

- Lateral movement pitch stroke allows highly precise moving and stopping at a high speed.

- It boasts high-level stopping accuracy of a pitch, ±0.1 mm.

- Comprehensive high rigidity guarantees uniform accuracy of roll-forged products. It also maintains excellent accuracy in long products.

Standard specifications

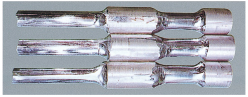

Usable with aluminum and square timber Example of products produced using forging roll

Manipulator

The servo motor is designed for lateral pitch move of the saddle. It reciprocates smoothly with high precision, and allows varied operation modes.

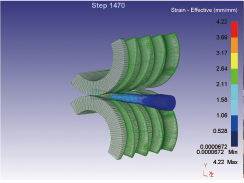

Die design

Forging and roll-forming simulation enable the recommendation of appropriate roll forms, as well as the design and production of roll dies.

Standard specs

| Model | FR260AF | FR360AF | FR460AF | FR560AF | FR660AF | FR960AF | |

|---|---|---|---|---|---|---|---|

| Inner segment outer dia. | mm | 260 | 360 | 460 | 560 | 660 | 960 |

| Inner segment effective width | mm | 320 | 450 | 570 | 640 | 700 | 1200 |

| Roll shaft distance adjustment | mm | 3 | 4 | 6 | 8 | 8 | 8 |

| Number of roll revolutions | RPM | 60 | 60 | 60 | 55 | 40 | 30 |

| Max. size of raw billet | mm, square | 45 | 60 | 75 | 100 | 120 | 160 |

| Clutch, brake | Air friction type | ||||||

| Required air pressure | MPa | 0.5〜0.7 | 0.5〜0.7 | 0.5〜0.7 | 0.5〜0.7 | 0.5〜0.7 | 0.5〜0.7 |

| Motor | kw | 11〜4P | 15〜4P | 30〜4P | 55〜6P | 75〜6P | 110〜6P |

| Oil lubrication | Full automatic circulation oiling system | ||||||

※Specifications above may be modified to meet users’ demands.